Metallurgical Casting Overhead Crane is depend on moving along the workshop orbital direction longitudinal and lateral movement of the car and the hook of the lifting movement for work, apply to metal smelting workshop, conform to JB/T7688.1-95 and JB

Tel:+86-373-7181222

Email:manager@zgjrjx.com

- Description

- Parameters

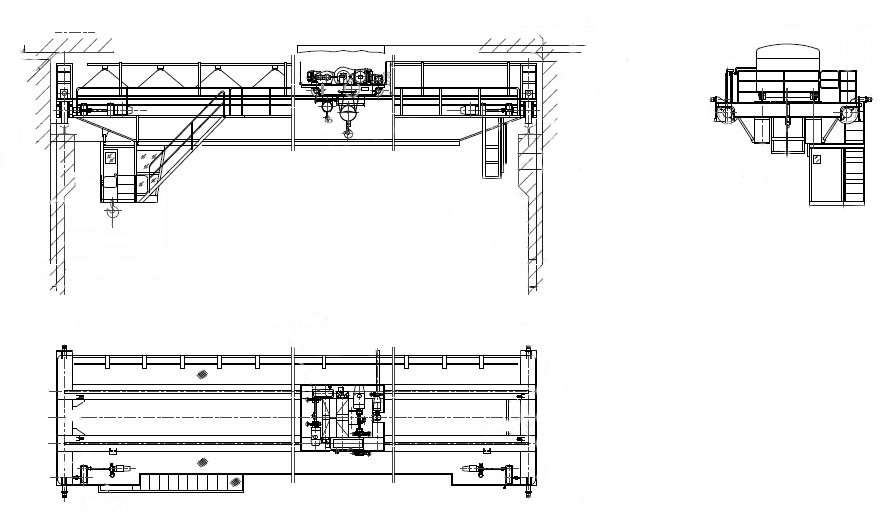

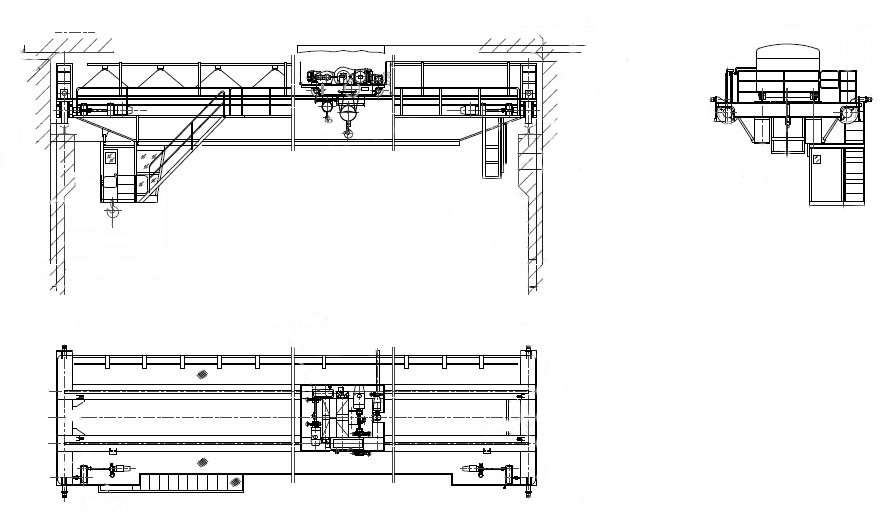

Metallurgical Casting Overhead Crane is depend on moving along the workshop orbital direction longitudinal and lateral movement of the car and the hook of the lifting movement for work, apply to metal smelting workshop, conform to JB/T7688.1-95 and JB/T7688.15-95 standard of special crane for lifting the molten metal.

Metallurgical Casting Overhead Crane is applicable to - 10 ℃ to + 50 ℃, environment temperature, under the temperature of 40 ℃ relative humidity is not more than 50%, the lifting of the molten metal forging clasps, board of radiation temperature does not exceed 300 ℃. Working Level of job: A7, A8 is used in the relatively busy metallurgy foundry.

Metallurgical Casting Overhead Crane (Foundry crane) is the main equipment during the steelmaking process in steelmaking workshop to transfer liquid steel or metal under the high temperature, dusty working environment. With the develpment of steel industry, the Metallurgical Casting Overhead Crane (foundry crane) need to work more frenquently. So the it must be safety and reliable, and even when some parts demaged.

Our Metallurgical Casting Overhead Crane can keep the ladle not falling or rollover. The framework is simple, and can be maintained very quickly in order to ensure the steelmaking production continuously.

Now we can supply Metallurgical Casting Overhead Crane (foundry crane) capacity up to 630 ton. Also according to customer's requirement we can provide special design.

b. Favorable performance

c. Soft starting and stopping

d. Safe and reliable traveling

e. Low noise, commodious cabin and good view

f. Convenient maintenance, excellent exchangeability for parts and components

g. Energy saving, reduce energy consumption

h. Using transducer for travelling or traversing crane to realize step speed or stepless speed change

i. Primer and finishing paint

j. Crane structure: steel box type

Metallurgical Casting Overhead Crane is applicable to - 10 ℃ to + 50 ℃, environment temperature, under the temperature of 40 ℃ relative humidity is not more than 50%, the lifting of the molten metal forging clasps, board of radiation temperature does not exceed 300 ℃. Working Level of job: A7, A8 is used in the relatively busy metallurgy foundry.

Metallurgical Casting Overhead Crane (Foundry crane) is the main equipment during the steelmaking process in steelmaking workshop to transfer liquid steel or metal under the high temperature, dusty working environment. With the develpment of steel industry, the Metallurgical Casting Overhead Crane (foundry crane) need to work more frenquently. So the it must be safety and reliable, and even when some parts demaged.

Our Metallurgical Casting Overhead Crane can keep the ladle not falling or rollover. The framework is simple, and can be maintained very quickly in order to ensure the steelmaking production continuously.

Now we can supply Metallurgical Casting Overhead Crane (foundry crane) capacity up to 630 ton. Also according to customer's requirement we can provide special design.

Metallurgical Casting Overhead Crane Advantage

a. Reasonable structureb. Favorable performance

c. Soft starting and stopping

d. Safe and reliable traveling

e. Low noise, commodious cabin and good view

f. Convenient maintenance, excellent exchangeability for parts and components

g. Energy saving, reduce energy consumption

h. Using transducer for travelling or traversing crane to realize step speed or stepless speed change

i. Primer and finishing paint

j. Crane structure: steel box type

| Capacity(main hook) | 5~450ton |

| Capacity(Aux hook) | as your requirement |

| Span | 7.5m-35m |

| Lifting height | 6m 9m 12m 18m 24m 30m |

| Lifting unit | Wire rope electric trolley |

| Industrial voltage | 380V50Hz3Phase or as your demand |

| Control method | Pendant push button remote controller or cabin control |

| Working temperature | -25°C ~ +42°C |

| Working class | A5 A6 A7 |

| Color of crane | Red yellow or as your demand |

| Raw material of crane structure | Q235 steel plate |

Leave Messages

Please Feel free to give your inquiry in the form below.We will reply you in 24 hours.